What is Methanol?

What is Methanol?

Heating value

MWh/t

H2 Storage

per ton MeOH

Methanol demand/year

Mio. tons

Density at 25°C

g/cm3

Heating value

MWh/t

H2 Storage

per ton MeOH

Methanol demand/year

Mio. tons

Density at 25°C

g/cm3

benefits of Methanol

1

Liquid at Atmospheric Pressure

2

Liquid at Temperatures

-98 °C to 65 °C

3

Hydrogen carrier with 4 H2 atoms

4

Natural Substrate of microbiological

Metabolism

benefits of Methanol

1

Liquid at Atmospheric Pressure

2

Liquid at Temperatures

-98 °C to 65 °C

3

Hydrogen carrier with 4 H2 atoms

4

Natural Substrate of microbiological

Metabolism

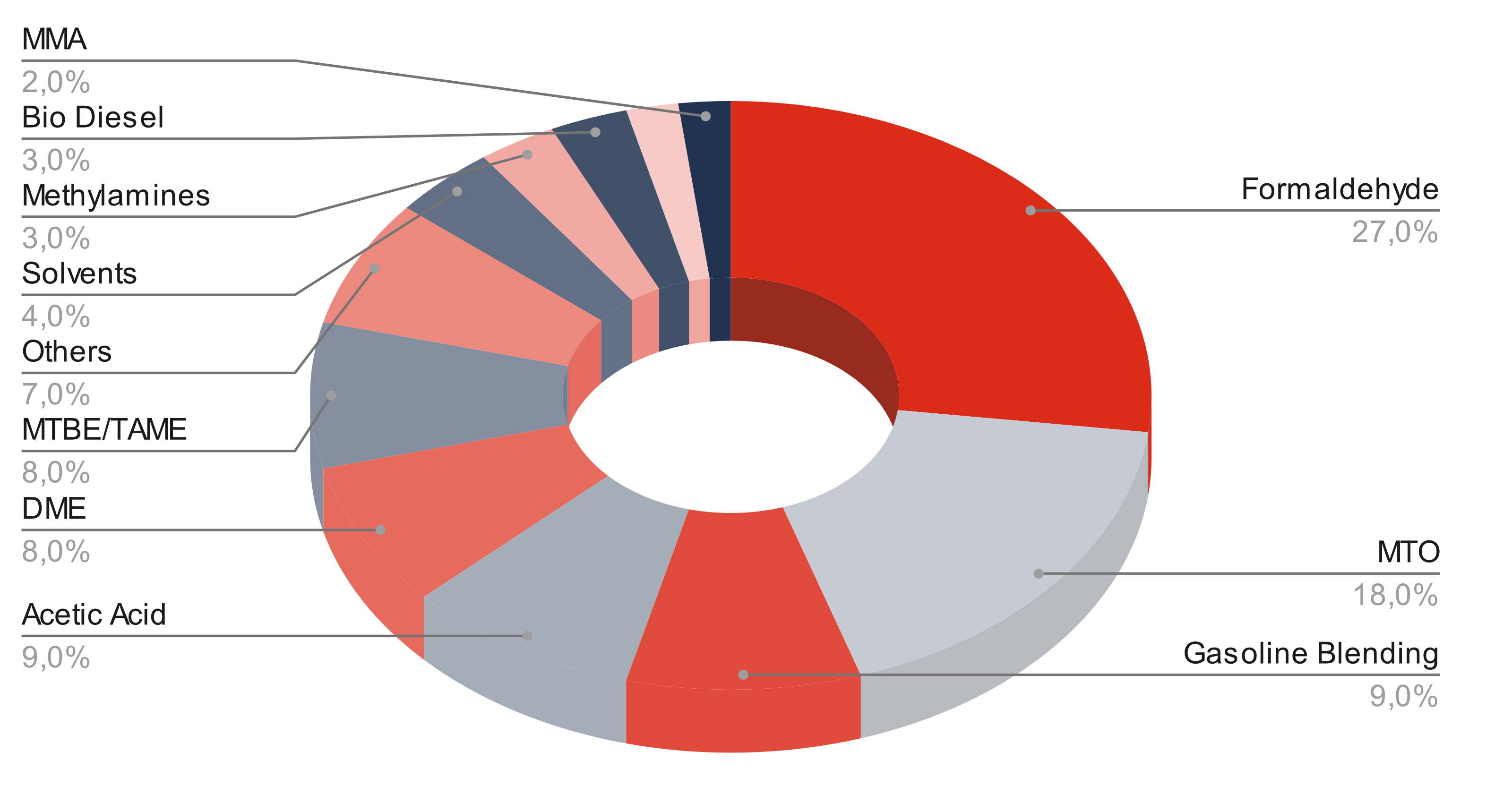

WHAT IS METHANOL USED FOR?

WHAT IS METHANOL USED FOR?

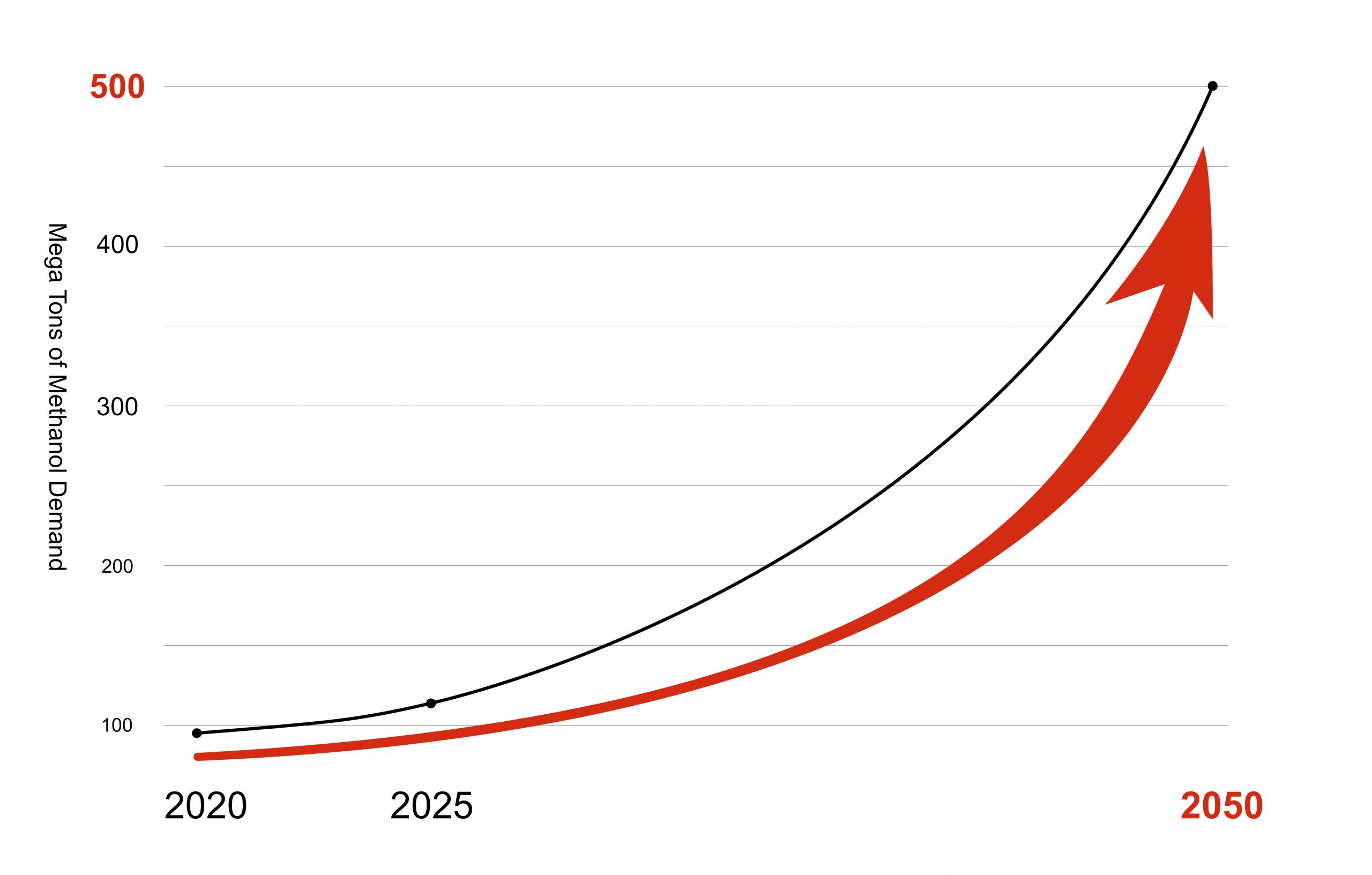

THE FORESEEABLE MARKET DEVELOPMENT

THE FORESEEABLE MARKET DEVELOPMENT

Source: International Renewable Energy Agency and Methanol Institute: “Innovation Outlook : Renewable Methanol”, January 2021

Today, fossil methanol is mainly produced from natural gas or from coal gasification. In all plants, the synthesis gas produced (carbon monoxide and hydrogen) is passed over a copper-zinc-aluminium catalyst under pressure and temperature and thus synthesised into methanol.

Global demand today is around 100 million tonnes.

Methanol can also be synthesised from the reactants carbon dioxide and hydrogen. Carbon dioxide can be captured from the air (DAC) or from point sources and thus contribute to climate protection.

The carbon is thus recycled and reused several times, avoiding additional fossil coallen fuel extraction and subsequently carbon dioxide emissions.

According to the publication of the International Renewable Energy Agency (IRENA), an e-methanol demand of 250 million tonnes is forecast by 2050 for the achievement of the Paris climate protection goals. To achieve these goals , IRENA recommends the construction of modular standardised plants.

THE METHANOL MARKET TODAY:

THE METHANOL MARKET TODAY:

Methanol (CH3OH) is a basic chemical with many uses and derivatives. Approximately 70% is used as a material. About 30% is used as an energy source.

Important derivatives are :

- Formaldehyde,

- Acetic acid, dimethyl ether (DME),

- Olefins Methyl tert-butyl ether (MTBE),

- Methyl methacrylate,

- Methyl chloride and methylamines.

Application in the energy sector today:

- MTBE

- Blending in petrol

- Biodiesel (FAME)

Use of methanol after end use

HOW IS OUR E-METHANOL PRODUCED?

HOW IS OUR E-METHANOL PRODUCED?

Methanol synthesis has been catalytically operated in large-scale industry since 1923.

CO2

0,04 – 100 %

From, air, flue gases and fermentation

CO2

0,04 – 100 %

From, air, flue gases and fermentation

CO2 Source

CO2 is purified from the flue gas or exhaust gas of combustion processes, biogas plants, fermtation processes of ethanol plants, steelworks, lime and cement industry in a high purity with significantly improved, biodegradable amine solutions.

Water

Electricity

Water

Electricity

ELECTROLYSIS

With the help of intermittent electrolysis, the surplus electricity is converted into H2. The conversion is open to the market with standardised electrolysis units.

Oxygen

O2

Heat

up to 80 ºC

Oxygen

O2

Heat

up to 80 ºC

METHANOL SYNTHESIS

The methanol synthesis is carried out by means of a recycle gas flow in an reactor using the catalyst.

The process conditions are adapted to those of the upstream and downstream processes and are highly thermally integrated.

The synthesis itself can be operated flexibly with a load change from min load to max load within a short time.

Methanol

CH3OH

purity of 65 %

Methanol

CH3OH

purity of 65 %

Methanol distillation

With high-capacity columns, the system overcomes typical design limitations. After distillation, the methanol achieves the globally recognised IMPCA quality.

Methanol

CH3OH

purity of 99,85 % (IMPCA)

Methanol

CH3OH

purity of 99,85 % (IMPCA)

CO2

0,04 – 100 %

From, air, flue gases and fermentation

Water

Electricity

CO2 Source

CO2 is purified from the air, flue gas or exhaust gas of combustion processes, biogas plants, fermtation processes of ethanol plants, steelworks, lime and cement industry in a high purity with significantly improved, biodegradable amine solutions.

ELECTROLYSIS

With the help of flexible electrolysis, the intermittent electricity is converted into H2 and oxygen. The conversion is open to the market with standardised electrolysis units.

METHANOL SYNTHESIS

The methanol synthesis is carried out by mean of a recycle gas flow in a reactor using the catalyst.

The process conditions are adapted to those of the upstream and downstream processes and are highly thermally integrated.

The synthesis itself can be operated flexibly with a load change from min load to max load within a short time.

Methanol distillation

With high-capacity columns, the system overcomes typical design limitations. After distillation, the methanol achieves the globally recognised IMPCA quality.

Oxygen

O2

Heat

up to 80 ºC

Methanol

CH3OH

purity of 65 %

Methanol

CH3OH

purity of 99,85 % (IMPCA)

CONTEXT E-METHANOL

Legal

Aligns with the goals of the Green Deal and the European “Fit for 55” package and climate protection goals formulated therein, in particular through the obligation to use renewable fuels (e-fuels).

Commercial

New value creation paths for industry due to increasing demand and low capacities of existing products (fuel, basic chemicals, energy and hydrogen carriers)

Society

Preservation of the environment & creation of jobs, circular economy, sustainable social development, avoidance of land consumption & biodiversity.

CONTEXT E-METHANOL

LEGAL

Aligns with the goals of the Green Deal and the European “Fit for 55” package and climate protection goals formulated therein, in particular through the obligation to use renewable fuels (e-fuels).

SOCIETY

Preservation of the environment & creation of jobs, circular economy, sustainable social development, avoidance of land consumption & biodiversity.

COMMERCIAL

New value creation paths for industry due to increasing demand and low capacities of existing products (fuel, basic chemicals, energy and hydrogen carriers)

You want to know more about Methanol?

You want to know more about Methanol?

Here you will find some useful links and tips: